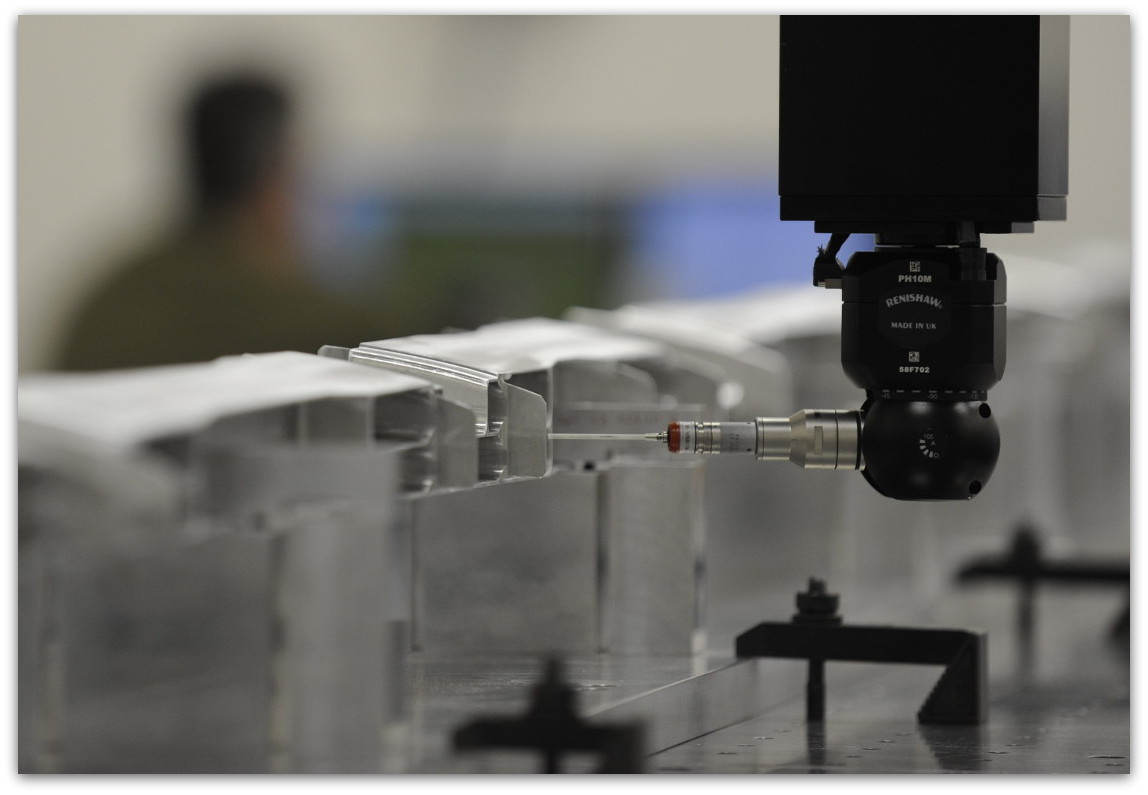

Precision

Providing complex and precise assembly has strengthened our customer relationships by providing additional needed value required in a changing industry. Our assembly department is designed around state-of-the-art, right sized equipment, and is experienced in large floor mounted and small bench top assemblies. AMT is capable of multi-component assemblies utilizing assembly jigs or DA technology. The assembly processes we offer include, but are not limited to, the following:

- Bearing installation

- Bonding and sealing

- Bushing installation

- Installation of rivets and various fasteners

- Pressing and swaging of bearing

- Staking

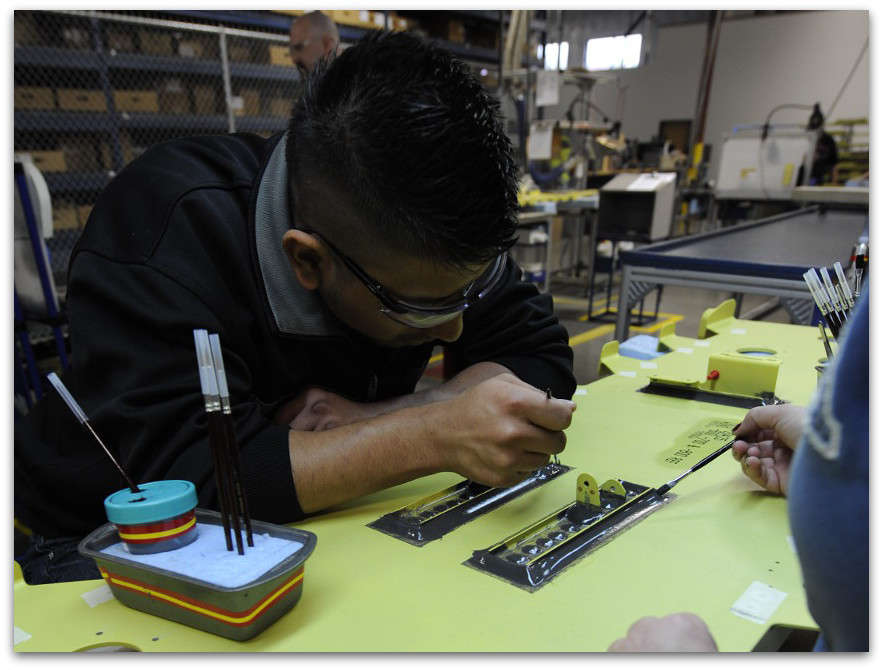

Bench Top

AMT provides complex and precise bench top assemblies of structural parts for our customers. Our trained and skilled assembly mechanics install a variety of solid aluminum rivets, Hi Loks, and fasteners into various assemblies for larger sub-assemblies or completed assemblies. They also work with various sealants and adhesives. Some of our bench top assembly processes include:

- Drilling close tolerance holes

- Sealant and adhesive applications

- Sub–assemblies for larger assemblies

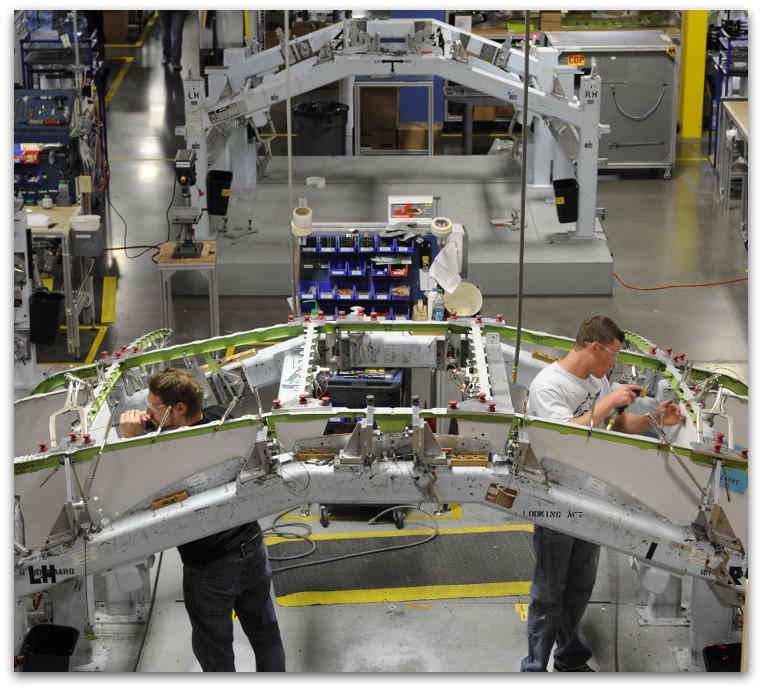

Major

AMT has several major assemblies that involve utilizing assembly jigs. Assembly mechanics locate, drill, and finalize assembly products by the use of assembly jigs and DA technology. Our assembly department is equipped with modern equipment and is experienced in large and small assembly jigs. A few of our major assembly skills and applications include:

- Mechanics use lean manufacturing processes to assemble products

- Use of custom tooling to assemble products

- Use of DA technology to assemble products